When you pick up a bottle of generic lisinopril or metformin, you expect it to work just like the brand-name version. You don’t think about where it was made, how it was tested, or whether a single batch might be dangerous. But every year, hundreds of these everyday medications are pulled from shelves-not because they’re ineffective, but because something went wrong in the factory. And what triggers that decision? It’s not always what you’d guess.

What Makes a Generic Drug Unsafe Enough to Recall?

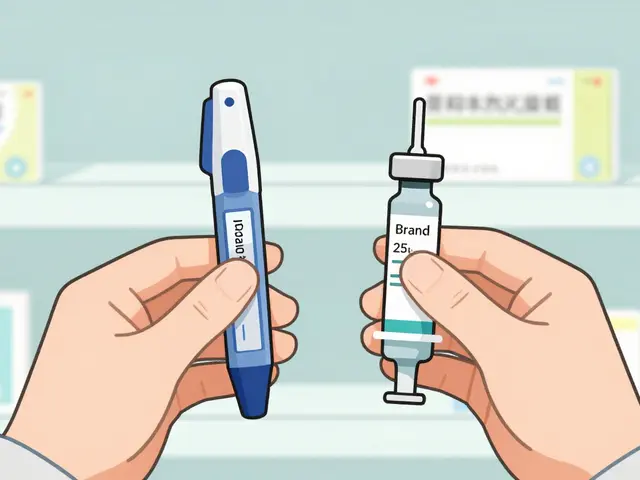

A drug recall isn’t about poor results or side effects you might feel after taking it. It’s about hidden flaws in the medicine itself. The FDA doesn’t wait for people to get sick. They act when they find proof that a batch violates strict manufacturing rules. The most common reasons? Sterility failures, wrong labeling, and incorrect active ingredient amounts. Take the July 2024 recall of potassium chloride injections. One vial was labeled as 10 mEq, but it actually contained 20 mEq. That’s a double dose. For patients with kidney problems, that could stop their heart. That’s a Class I recall-the highest level. It means there’s a real chance of death. The FDA doesn’t need to wait for a death to happen. They act when the risk is clear. Other recalls are less deadly but still serious. In April 2025, Glenmark Pharmaceuticals pulled nearly 40 generic drugs because their Indian factory wasn’t meeting cleanliness standards. Mold spores, dust particles, even bacteria in the air could end up in your pills. These aren’t accidents. They’re failures in systems that should prevent them.How the FDA Classifies the Risk

Not all recalls are created equal. The FDA uses three levels to tell you how urgent the problem is:- Class I: Could cause serious harm or death. Examples: wrong dosage, contaminated sterile injectables, missing active ingredient. In 2024, 52% of recalls fell into this category.

- Class II: Might cause temporary or reversible health issues. Think: labeling mistakes, pills with the wrong color or shape, minor potency issues. This was 35% of recalls in 2024.

- Class III: Unlikely to hurt you, but still breaks the rules. Maybe the expiration date is smudged, or the bottle says "take with food" when it shouldn’t. Only 13% of recalls are here.

What Really Starts the Recall Process?

Most people think the FDA finds the problem first. They don’t. In 98% of cases, the manufacturer spots it first and tells the FDA. That’s voluntary. It sounds good-industry self-policing. But here’s the catch: companies delay. Sometimes for weeks. Sometimes for months. The triggers aren’t mysterious. They’re measurable:- Sterility failures (37%): Bacteria or fungi in injectables or eye drops. These are the scariest. A single contaminated vial can kill.

- Particulate matter (12%): Tiny bits of glass, metal, or plastic in the solution. Seen in IV bags and inhalers.

- Labeling errors (9%): Wrong dose, wrong drug name, missing warnings. Easy to fix, hard to catch.

- Active ingredient issues (7%): Too much or too little of the medicine. Metformin recalls in 2023 were mostly due to NDMA contamination-cancer-causing impurities.

Why Foreign Factories Are the Big Problem

About 80% of the active ingredients in your generic drugs come from India and China. But the FDA doesn’t inspect those factories like they do U.S. ones. Domestic plants? Inspected every 1.8 years on average. Foreign plants? Every 4.6 years. That’s not a typo. It’s a gap. And it’s dangerous. The Glenmark recall in 2025 wasn’t caught by the FDA. It was exposed by journalists. The company had been flagged for violations since 2019. But no inspector had stepped foot in their Indian facility in over four years. That’s not oversight. That’s luck. The EU has mandatory reporting. If a company finds a problem, they have to tell regulators within 24 hours. In the U.S., companies can wait. And many do. The average time between finding a problem and telling the public? 42 days. In the EU? 18.What Happens When a Recall Is Issued?

Once the FDA approves the recall, the manufacturer has to do three things:- Stop shipping the product.

- Notify distributors and pharmacies.

- Ask customers to return the product.

How Healthcare Providers Handle It

Hospitals and pharmacies don’t wait. They have systems. ASHP guidelines say they must:- Put recalled products on a "do not purchase" list in their ordering system.

- Train staff to recognize recall notices within 24 hours.

- Notify patients within 72 hours.

- Keep records for six years.

What’s Changing-and What’s Not

The system is under pressure. In 2025, the FDA announced a new plan: inspect high-risk foreign factories every year instead of every 4.6. That’s a start. But the agency only has funding for 17% of the inspections it needs. Congress hasn’t approved the $780 million more per year to fix it. New tech is helping. Blockchain is being used by 18% of major manufacturers now-up from 3% in 2023. That means every step of a drug’s journey is tracked digitally. If a batch is bad, you can pinpoint it in hours, not weeks. AI tools are being trained to predict failures before they happen. The FDA is spending $47 million on this. It’s early, but promising. Meanwhile, the top 10 generic drug makers now control 65% of the U.S. market. That means one failure can affect millions. And with 27% more recalls since 2020, the problem isn’t shrinking. It’s just getting more visible.What You Can Do

You can’t control the factory. But you can protect yourself:- Check the FDA’s Enforcement Reports monthly. It’s free. Search by drug name or lot number.

- Don’t panic if your drug is recalled. Call your doctor or pharmacist before stopping it.

- Keep the original bottle. The lot number is on it. That’s your key to knowing if you’re affected.

- Sign up for FDA recall alerts via email. It’s simple. Go to fda.gov/medwatch.

- Report side effects-even if you’re not sure. The FDA’s MedWatch system needs more data.

Is Your Generic Drug Safe?

Yes. Most are. The system works more often than it fails. But safety isn’t automatic. It’s built-brick by brick-through inspections, reporting, and transparency. When any one of those breaks, the risk rises. The next time you pick up a generic pill, remember: it didn’t just appear. Someone tested it. Someone inspected it. Someone decided it was safe. And if something went wrong, someone had to say: "Stop. This isn’t right." That’s the quiet work of drug safety. And it’s not over.What should I do if my medication is recalled?

Don’t stop taking it unless your doctor tells you to. Some recalls are for minor issues, and stopping suddenly can be dangerous. Contact your pharmacist or doctor. They’ll tell you if you need a replacement or if it’s safe to keep using it. Always check the lot number on your bottle against the recall notice.

How do I know if my generic drug is from a recalled batch?

Look at the lot number on the bottle or box. Compare it to the list on the FDA’s Enforcement Reports page. If you don’t have the bottle, call your pharmacy. They keep records and can check for you. Don’t rely on the drug name alone-many generics have the same name but different lot numbers.

Why do so many recalls come from India and China?

Because those countries produce about 80% of the active ingredients in U.S. generic drugs. But the FDA inspects their factories far less often-once every 4.6 years on average-compared to every 1.8 years for U.S. plants. That gap means problems go undetected longer. It’s not that the factories are worse-it’s that they’re watched less.

Are generic drugs less safe than brand-name ones?

No. Generic drugs must meet the same FDA standards for quality, strength, and purity as brand-name drugs. The difference isn’t safety-it’s manufacturing oversight. Most recalls happen because of supply chain issues, not because generics are inherently inferior. The same active ingredient is used. The same tests are required.

Can I trust the FDA to catch dangerous drugs before they reach me?

The FDA catches most problems before they cause harm-but not all. Their inspection system is underfunded, especially for foreign factories. That’s why it’s important to check recall notices yourself. Don’t wait for a letter. Visit fda.gov/medwatch and sign up for alerts. Your awareness is part of the safety net.

Cassie Widders

January 13, 2026 AT 23:11Just saw my metformin batch got recalled last week. Never even knew it was a thing until my pharmacist called. Scary how little we’re told.

Still took it for three days before I found out. Don’t panic, but check your lot numbers. Seriously.

Rebekah Cobbson

January 14, 2026 AT 13:46I’m a nurse and I’ve had to call over 200 patients after recalls. Most of them freeze up. They think if it’s recalled, it’s poison. But sometimes it’s just a mislabeled cap.

Always talk to your provider first. Stopping blood pressure meds cold turkey is way riskier than taking a slightly off batch for a few days.

Also-keep your original bottles. That lot number is your lifeline.

Sonal Guha

January 15, 2026 AT 10:57India makes 80 of the world’s generics and you act like its a conspiracy

US pharma stopped making stuff because its too expensive

Stop blaming the developing world for your overpriced healthcare system

Also the FDA inspects US plants more because they can

They dont fly to India for coffee breaks

Alice Elanora Shepherd

January 16, 2026 AT 08:30There’s a lot here, and it’s all true-but the real issue isn’t foreign factories, it’s underfunding. The FDA has a mandate to inspect every facility every 2–3 years. They’re legally required to. But they’ve been under budget since 2010.

They can’t do the job. Not because of corruption. Not because of bias. Just because they don’t have enough inspectors, enough flights, enough time.

It’s not a scandal. It’s a systemic failure. And it’s fixable-if we vote for it.

Jay Powers

January 16, 2026 AT 13:04I get why people freak out about recalls but honestly most of these are caught before anyone gets hurt

Think about it-how many times have you heard of someone dying from a generic drug recall

It’s rare

And the fact that companies report it themselves means the system is working better than you think

Yes the inspections are too slow

Yes the delays are frustrating

But we’re not living in a horror movie

Most pills are fine

And the ones that aren’t? They’re pulled before they reach you

Trust the process, but stay informed

That’s all

Lawrence Jung

January 17, 2026 AT 01:09Let’s be real

Generic drugs are a compromise

Brand name? Made in Ohio with FDA breathing down their neck

Generic? Made in a warehouse in Hyderabad with a guy checking labels on a tablet

Same chemical? Yes

Same soul? No

And that’s why people get scared

It’s not about the pill

It’s about the lack of care behind it

We outsource safety because we outsource everything

And now we’re surprised when the machine breaks

Wake up

It was always going to happen

Sona Chandra

January 18, 2026 AT 10:04US is just mad because India makes cheaper drugs and they can’t compete

Why don’t you build your own factories

Why don’t you pay workers properly

Why don’t you stop blaming the poor for your greed

80 of your drugs come from India because we’re better at it

And your FDA? They’re too lazy to fly here

Not our problem

TiM Vince

January 19, 2026 AT 14:50My grandfather takes six generics. He doesn’t know what a lot number is.

He trusts his pharmacist. He trusts the FDA. He trusts that the pill he swallows won’t kill him.

And he’s right 99.9 of the time.

But that 0.1? It’s the one that haunts you.

I work in supply chain. I’ve seen how fragile this system is.

It’s not broken. It’s just stretched thin.

And the people who need it most? They’re the ones who can’t check the website.

We need better communication. Not more inspections. Just better info.

Konika Choudhury

January 21, 2026 AT 08:21India has the most advanced generic drug manufacturing in the world

US wants to control everything

They don’t want competition

They want to charge you $500 for a pill that costs $2 to make

Recalls? That’s propaganda

We follow WHO standards

You follow Wall Street standards

Who’s really unsafe?